Engineer and developer who solves problems with hardware, software, and automation. Building performant, modular, and reliable systems-from embedded devices and robotics to virtualization and infrastructure automation.

Software and Embedded Systems Development

▸

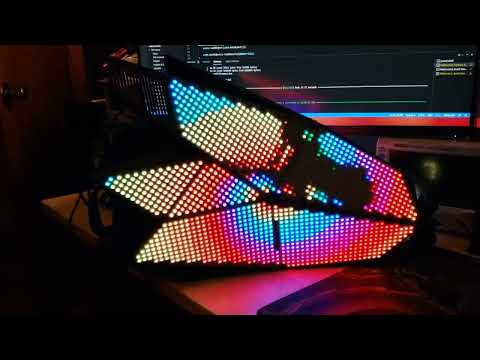

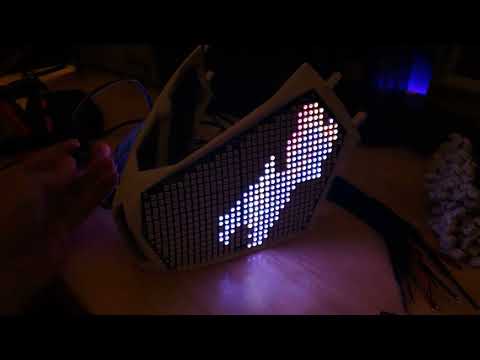

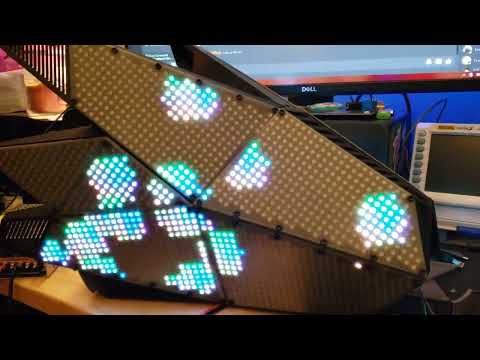

ProtoTracer: Embedded 3D Rendering Engine

| Website | GitHub |

Contributors on GitHub

|

2020 - Now

|

|

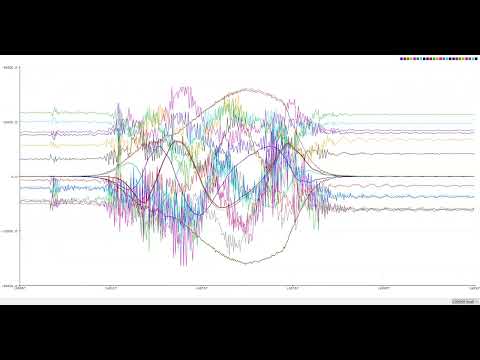

ProtoTracer is a C++ based 3D rendering engine optimized for microcontrollers. It calculates dynamic 3D scenes in real-time, reacting to sensor or user inputs to adapt the output. This software is designed to be modular for use in other projects.

This includes features such as:

- Keyframed animations with support for automated easing

- Display of custom converted FBX, OBJ 3D Models with support for textures using any static image format as well as support for animated GIFs

- Custom camera definitions and parameters for specialized display shapes and 3D outputs

- Support for driving HUB75, WS2812, and APA102 based LED displays, with controller definitions making it easy to create other interfaces

- Raster-based 3D rendering as well as Raytraced rendering

- Segmented-rendering optimization using quadtrees

- Custom rendering pipeline optimized for high frame rates on constrained hardware

- Enables PS1-level graphics rendering

- Custom static and animated shader materials

- Simplex Noise Shaders

- Audio Reactive Shaders (Oscilloscope/Spectrum Analyzer)

- TV Static emulation

- Gradient/Normal/UV Tiled/Depth Materials

- Audio Analysis

- Voice analysis for matching vowel sounds to viseme shapes

- Allows user calibration for custom formant maps

- Fourier Transform for analysis/spectrum analyzer display

- Filtering and automatic scaling for background noise

- Filters: FFT/Kalman/Peak/Ramp/Running Average

- Physics Simulator

- Hardware Support for:

- SSD1306 Status Display/HUD

- Communication with secondary controller for wireless control

- PWM Fan Controls through a user menu

- APDS9960 Color/Distance Sensing

- BNO055 Quaternion input for space-mouse like control

- MMC56X3 Magnetometer input

- SHARPGP2Y Distance Sensing

- MAX9814/SPW2430 Microphone Input

- Screenspace Shaders for manipulating 3D rendered frames with 2D modifications

- Fisheye distortion

- Glitch distortion

- Box/Radial blur

- Magnetic Lens distortion

- Phase Shifting

- Live object manipulation

- Position/Scale/Rotation

- Distortion with custom object deformer

- Modifies 3D space via transformation functions

- Perspective Deform

- Sinusoidal Deform

- Dropwave Deform

- Automatic 3D object alignment

- Allows alignment of center of volume or mass to a target coordinate

- Fit alignment to a plane

- Allows users to rapidly add their own model with any scale/rotation and it will autofit to a target size and plane

- Custom Optimized Math Library

- Rotation library with support for Axis Angles, Direction Angles(Custom), Euler Angles, Quaternions, Rotation Matrices, Yaw-Pitch-Roll

- Vector2D and Vector3D Library

- Quaternion Library

- Kalman and Running Average Filters for Quaternion Space, Cartesian Space

- Automated Testing to verify custom math libary

Doxygen genereated documentation from sourcecode:

|

▸

AetherControl: Optimized CNC Firmware

| GitHub |

Solo Project

|

2023 - Now

|

|

AetherControl is a streamlined and modular, C++ based motion-control firmware. It is built for real-time G-code parsing, motion planning, kinematics, and stepper-motor drive. Supports advanced kinematics like Stewart platforms, CoreXY machines, and Cartesian robots with dynamic trajectory planning.

Implementations:

- High-Speed CoreXY pick-and-place machine

- High-Speed 6x 1000W AC Servo based 6-axis Stewart platform used as a flight simulator

This includes features such as:

- Support for Stewart platform, Cartesian, CoreXY, and custom kinematics configurations

- Dynamic trajectory planning with velocity and acceleration constraints

- G-code parsing and execution for CNC command interpretation

- Real-time multi-axis synchronization and motion coordination

- Multi-Controller synchronization

- Layered modular architecture for easy customization and extension

- Support for sensor calibration and automated testing routines

- Optimized for ARM Cortex-M microcontrollers with efficient resource use

- Custom PathPlanner optimizing for up to the number of GPIO pins available to drive the system

|

▸

ProxmoxScripts for Automated Infrastracture Management

| Website | GitHub |

Contributors on GitHub

|

2024 - Now

|

|

ProxmoxScripts is a collection of Bash scripts for streamlining and automating the management of Proxmox Virtual Environment (PVE) clusters. This was developed to help manage and automate Proxmox virtualization infrastructure. The scripts are accessible via a console-based menu for overview, navigation, and execution. Users can read help information for each script as well as get a description of required parameters.

Features include:

- Cluster configuration tools

- Adding Nodes - Remote configuration with IP

- Cluster Creation - From list of IPs

- Cluster Deletion - Separating all nodes from cluster

- Firewall management

- Bulk LXC/VM Firewall Management

- Automated host default firewall configuration

- High Availability

- Create HA Group and add nodes

- Bulk add LXC/VMs to HA group

- Host Automation and Configuration

- Remove local-lvm storage and expand local storage (for Hyper-Converged setups)

- Bulk Microcode configuration/Timezone Configuration/Upgrades

- Generic PWM and Dell IPMI hardware fan control adapting to CPU temperatures

- Enable CPU Scaling Governer

- Enable GPU Passthrough to VM

- Enable IOMMU

- Enable GPU Sharing with LXC

- Optimize for X3D hardware

- Live memory testing

- System optimization for nested virtualization

- LXC and VM Configuration and Management

- Networking

- Bulk adding network bonds

- List all VM/LXC IDs with their associated MAC address

- Bulk set DNS on cluster

- Find VM ID from MAC address

- Automated host-to-host network speed test

- Bulk update network interface names

- Bulk host uplink speed test

- Remote VM/LXC Management

- Integration with Apache Guacamole

- Bulk add/delete RDP connections

- Bulk add/remove SFTP server to RDP connections

- Bulk list RDP configuration

- Bulk update/remove drive redirection

- Pull Guacamole authentication token

- Configuration of virtual machine static IPs over SSH for Debian/Ubuntu/Windows

- Generate a resource report for all VMs/LXCs

- Automated penetration testing/port scanning

- Storage Automation

- Ceph Configuration

- Bulk create OSDs

- Edit crushmap (decompiles, prints directory, allows user edit, then recompile)

- Bulk restart managers/monitors/metadata servers/OSDs

- Set pool to minimum size of 1 and to a size of 1 (testing/temporary data)

- Create automated deep scrubbing with a chron job

- Automate creating a single drive Ceph node (shares host OS and Ceph data)

- Bulk OSD sparsify

- Bulk start stopped disks

- Full data wipe on specified disk (clear Ceph and all remnants of user data)

- Disk Benchmarking

- Bulk VM disk deletion

- Bulk VM disk deletion for disks with snapshots

- Trim all filesystems of resources using Qemu Agent or LXC

- Automate disk spin down

- Pass host directory to LXC

- Update stale mounts

- Custom User Interface library

|

▸

OpenDACT: Automatic Delta Kinematics Calibration Software

| Github |

Contributors on GitHub

|

2014 - 2017

|

|

OpenDACT (Open-source Delta Automatic Calibration Tool) is a calibration tool for delta robots. It calibrates generic delta robots and automates calibration of Repetier-firmware-controlled delta robots (primarily 3D printers). The calibration uses forward and inverse kinematics measurements to make adjustments. It takes Z-height readings at key XY points on a flat plate (print bed) to iteratively calculate hardware offsets. Users can manually adjust hardware or apply software offsets to correct for imperfections.

This software solves for the following mechanical offsets:

- Diagonal rod lengths

- End effector radius

- Horizontal radius

- Endstop offsets

- Angles of the ABC towers

For Repetier based robots, these offsets are automatically saved on the controllers EEPROM upon a successful calibration. Z-bed distortion on a newly completed build could have offsets of +/- 2mm across the plate, this tool (assuming issues in the above offsets) can calibrate the systems down to 5-10 microns.

This software has been tested and successfully used on small-form factor deltas (100mm plate diameter) and large-form factor deltas (1.5 meter plate diameter).

|

▸

Proxmox VE Load Balancer

| GitHub |

Solo Project

|

2025 - Now

|

|

ProxmoxLoadBalancer is a Python tool that balances memory across Proxmox VE cluster nodes. It has two modes of operation:

- Simulation Mode: Test and visualize load-balancing algorithms in a controlled environment without touching the live cluster.

- Live Mode: Uses the Proxmox API to monitor memory usage and migrate VMs to balance load.

This software is built as a stand-in until ProxmoxVE ships with a built-in cluster load balancer.

|

▸

Teensy WebHID Firmware Loader

| Example Page | Github |

Solo Project

|

2025 - Now

|

|

The Teensy WebHID Loader is a Chromium-based firmware flasher replicating PJRC’s Teensy Loader. It parses and uploads HEX and BIN files to Teensy microcontrollers, manages serial connections, and lets end users update device firmware without installing any software.

|

▸

Proxmox GPU Passthrough for Workstations

| GitHub |

Solo Project

|

2025 - Now

|

|

A guide to running Proxmox VE as the base operating system for a high-performance workstation. Covers GPU and USB controller passthrough; multi-NUMA-node CPU optimization; BIOS and GRUB tweaks; VFIO module setup and driver blacklisting; microcode updates and GPU ROMs; tuning CPU affinity; network-stack optimizations; Windows/QEMU adjustments for Easy Anti-Cheat compatibility; example VM setups; and benchmarking results.

This enables users to run high-performance workstations in various configurations while keeping things easy to manage, since each VM can be tuned for its specific OS or software.

|

Product Prototyping and Engineering

▸

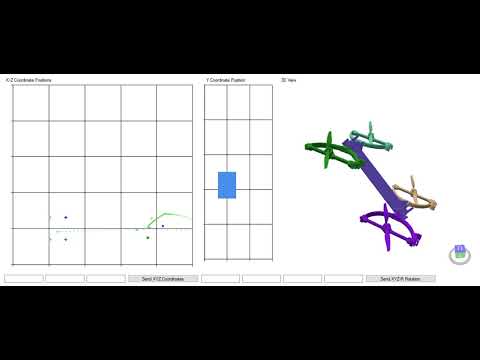

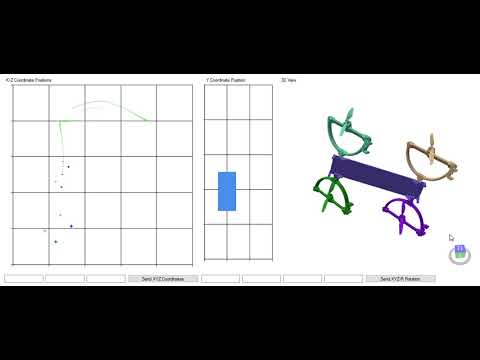

Stewart Platform - Firmware and Hardware for Flight Simulator

| Github |

Hardware/Software Solo | Research by Co-workers

|

2020 - Now

|

|

The Stewart Platform project is an adaptation of a commercial system. The machine originally shipped with MDBox motion controllers, controlled via ethernet. Because of high latency it was adapted with a custom controller, upgraded 1000W AC servos for the linear actuators, and custom firmware and software. This was the start of the AetherControl project detailed above. The attached repository contains the interface code that takes target XYZ Cartesian coordinates and Euler rotations, then computes the six actuator lengths for AetherControl. The goal of the project was to adapt the system to handle high-frequency vibration and high-speed motion for research on flight dynamics.

The inverse kinematics repository allows for custom user-defined configuration parameters, taking in:

- Base Plate Radius

- Base Plate Mounting Angle

- Platform Plate Radius

- Platform Mounting Angle

- Base Height

- Maximum Actuator Length

Users can input an XYZ cartesian coordinate and Yaw-Pitch-Roll to get a returned value of each of the 6 actuator lengths.

|

▸

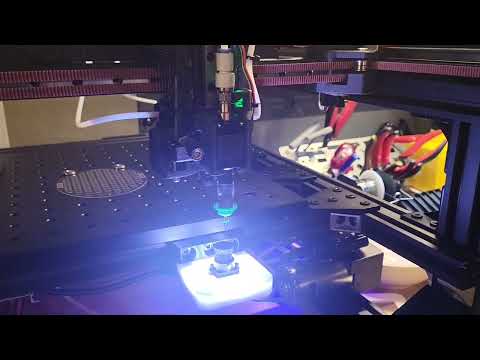

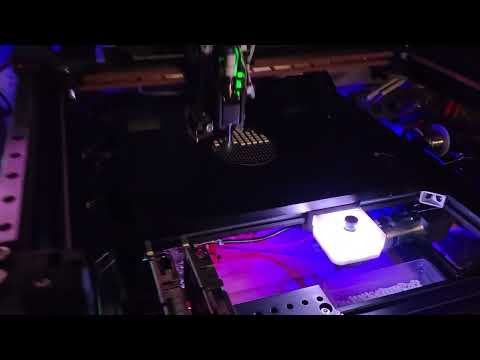

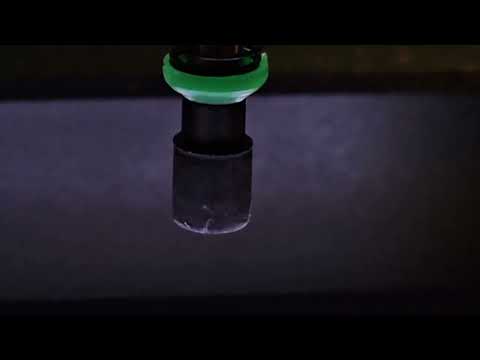

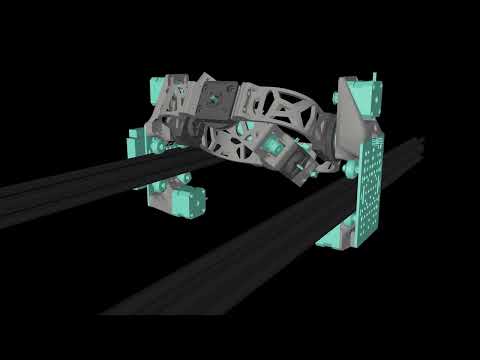

Custom High-Speed CoreXY Pick-and-Place

| Github |

Solo Project

|

2021 - current

|

|

This project started was to create a small yet capable Pick-and-Place machine. This machine has been used to manufacture RGB LED displays which each have over 500 LEDs, power distribution boards, custom LED control electronics, etc.

Features:

- OpenPNP for software control

- This system supports most of the hardware calibration features provided by OpenPNP

- CoreXY design based on the Voron project’s motion system

- Closed-loop AB motors for X and Y axes

- Feedrates up to 800mm/s

- Accelerations up to 40m/s^2

- 12 Pneumatic feeders

- Dual controller design

- Primary controller for controlling closed-loop AB motors for the CoreXY motion system

- Secondary controller for integrated USB hub to connect cameras/controller, Z and rotation axis stepper motor control with TMC2209 stepper drivers

- 120 fps cameras with fixed exposure and white-balance settings

- Fiducial camera for alignment of X and Y positions as well as fine-tuning the motion system backlash and pick-up locations

- Part camera for alignment of parts/components

|

▸

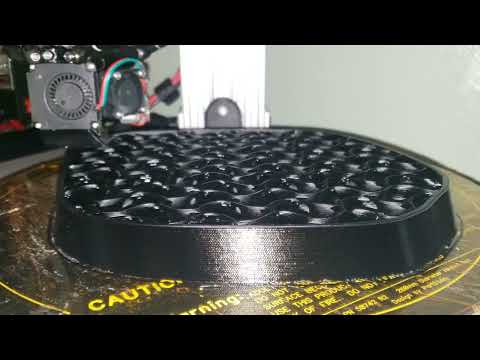

Custom High-Speed Delta 3D Printer

|

Solo Project

|

2014 - 2019

|

|

This project started in the era of the Prusa Mendel/i3 designs. Required faster print times than available 3D printers in the market, designed and built this system to solve that problem.

Features:

- 270mm build diameter

- ~490mm build height

- Printing travel speeds up to 500mm/s

- Printing speeds with extrusion up to 150mm/s (layer height dependent)

- Accelerations up to 10m/s^2

- 32-bit controller using Smoothieware/Marlin (previously 8-bit with Repetier)

- Custom frame and design

- Custom, compact end-effector and extruder combo

- Automatic bed leveling using FSRs integrated into the bed mounts

|

▸

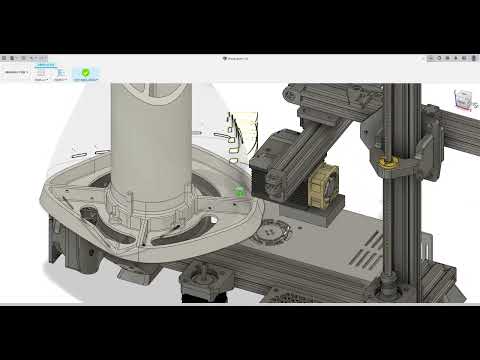

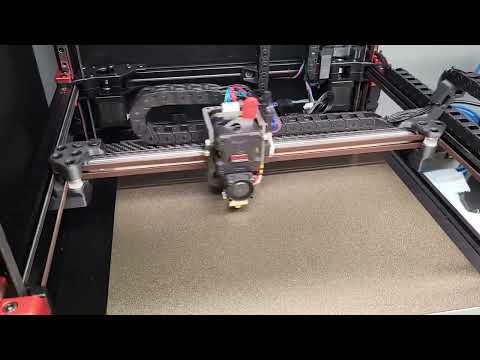

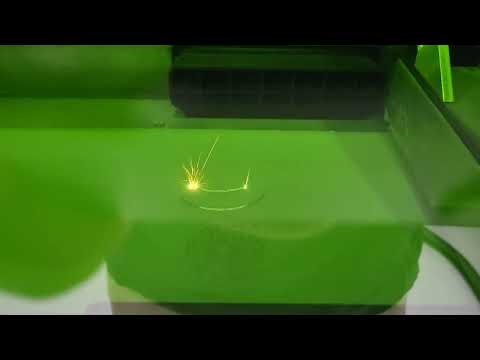

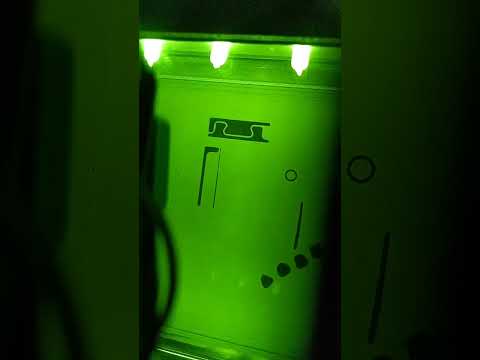

Custom 4-Axis Machines and Fusion 360 Post Processors

| Github |

Solo Project

|

2023 - 2024

|

|

This project primarily is a custom-built Fusion 360 post-processor for multi-axis laser cutting and engraving. It was created to cut complex shapes into vacuum-formed plastic visors. The software is a Fusion 360 post-processor that uses the machine’s hardware configuration to convert 4-axis toolpaths into G-code for a custom 4-axis laser cutter.

The machine is an XYZ motion system with an additional large rotary axis that has an integrated fume exhaust system.

|

▸

4-Axis Automated Gimbal for MEMS-Based Motion Processor Testing

| Github |

Solo Project

|

2018 - 2020

|

|

The 4-axis gimbal is the primary tool in a larger project. This project required accurate calibration of low-cost MPU6050 motion sensors. To perform the calibration a custom 4-axis motion system (3 rotational axes and 1 linear axis) closely follows a path while capturing the data (acceleration/angular velocity and for some also the magnetic field) from multiple inertial measurement units. A separate tool-the linked GitHub repository-simulates the system and generates ideal theoretical sensor outputs. Comparing real and simulated data is used to calibrate the system and develop filters for the sensors adjusted outputs.

|

▸

Power Electronics and Control Systems

|

Solo Projects

|

2014 - Now

|

|

Designed and built custom power-conversion, motion‑control systems, and other electronics:

- Custom Buck Power Regulators: Gallium nitride-based buck converters stepping 60 V down to 5 V at up to 20 A

- LoRa Remote Firework Igniter: 12-channel, 2 A LoRa-based firework-igniter controller prototype

- Haptics Research Motor Driver: DC motor driver with sensor feedback for inverted-pendulum and force-feedback experiments

- High‑Speed Pick‑and‑Place End-Effector Controller: High-speed pick-and-place end-effector controller: board with onboard power regulation, a 4-port USB hub for cameras and motion control, and two TMC2209 stepper drivers

- Stroboscope: High‑frequency LED stroboscope for motion analysis and AC/DC motor testing.

- Controller for High-Speed Pick‑and‑Place: CNC control board handling six stepper motors, twelve MOSFET channels for pneumatics, and integrated power regulation

- 8‑Channel HUB75 + WS2812 LED Matrix Driver: LED controller integrating HUB75 logic (row/column multiplexing) and 8-channel 500 count addressable strips

- Wireless WS2812 LED Strip Controller: ESP32 and Teensy 4.0‑based 8-Channel LED Strip controller - able to drive up to 4,000 LEDs

- ESP8266 + BME280 Environment Monitor: ESP8266 + BME280 environmental monitor: wireless temperature and humidity logger with web dashboard

- SMT PCB Panelization Workflow: Panelized PCBs for small‑batch pick‑and‑place and reflow assembly

|

▸

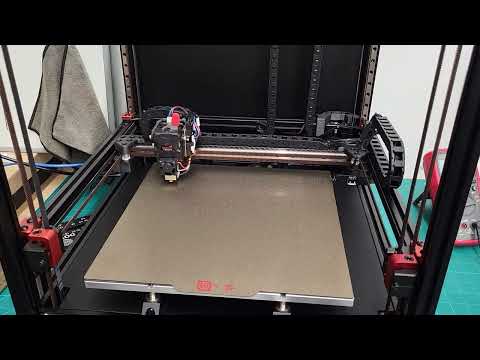

Customized Voron CoreXY 3D Printer

|

Solo Project

|

2019 - 2021

|

|

A custom 3D printer derived from the Voron project, built to explore the limits of FDM additive manufacturing.

- Extrusion and Motion Hardware

- BondTech LGX extruder with Mosquito Magnum hotend for high flow

- 48V powered stepper drivers with accelerations up to 2g (20m/s^2) and travel speeds near 600 mm/s

- Reinforced Structure

- Continuous carbon‑fiber-reinforced parts printed on the Markforged Mk2, plus a custom carbon‑fiber X‑gantry

- Firmware and Calibration

- Klipper firmware with computation offloaded to a Raspberry Pi

- Custom-tuned to maximize performance within the system’s limits

|

▸

Wearable 3D Printed Designs with Integrated Electronics

| Github |

Solo Project

|

2020 - Now

|

|

Designed and built 3D-printable cosplay hardware-currently have six designs in total. For the Beta, Delta, Epsilon, and Sigma, each model is available on GitHub as STL files optimized for common 3D printers. Every project includes an electronics wiring guide, custom ProtoTracer firmware binaries, and source code.

The Alpha and Gamma prototypes use real-time stereoscopic passthrough vision with a custom lens stack and display module. The vision-systems use modified software (running on a Raspberry Pi CM4) to reduce latency to about 15 ms and support the stereoscopic live synchronized display. This leaves as much area as possible for the LED displays. Each uses two synchronized microcontrollers to render live 3D graphics on the full-face displays. Integrated front-facing distance sensors and a 9-axis IMU modify the animation pipeline, so animations react instantly to motion and proximity.

|

▸

Dual-Tilt Rotor Quadcopter

| GitHub |

Software Solo | Hardware by Co-Workers

|

2018 - 2019

|

|

This project is an integrated control system for a quadcopter with independently tilting rotors. Each motor can pivot on two axes, letting the quadcopter perform complex maneuvers and fly at any angle. This was designed as a system to allow the quadcopter act as a gimbal to allow for a larger statically mounted camera while having a full 360 degree view.

Software Stack:

- Control algorithms in C++ for real-time dynamics

- C#-based physics simulation with a C++/CLI bridge and control-structure library for tilt-rotor modeling

Hardware Integration:

- Runs on a Raspberry Pi for onboard flight control

- Uses a PCA9685 16-channel PWM driver to manage motor speed and tilt servos

- TCA9548A I2C multiplexer with multiple IMUs (MPU6050/MPU9150) for attitude sensing

Highlights:

- Custom pipelines for planning aerial maneuvers and stabilizing flight

- Sensor fusion and control loops for autonomous operation

|

▸

Other Product Prototyping, Engineering, and Software

- Electrospinner: Designed and built an automated electrospinning device for researching polymer nanofibers (With Co-Worker)

- Custom Print Farm: Designed and built custom compact and portable CoreXY stackable 3D printer farm (With Co-Workers)

- Tripteron 3D Printer: Developed a Cartesian-parallel 3D printer prototype

- Reflow Heater Controller: Created hardware and firmware for a reflow heater, featuring PID temperature control and programmable profiles

- Printer Conversion for PEEK/Ultem: Modified a Stratasys FDM printer’s hot end, control electronics, and build chamber to print high-temperature materials (PEEK/Ultem/Polycarbonate)

- Ozone Water Treatment System: Created a residential ozone generator for point-of-entry water sanitation, including ozone injection and feedback control with dissolved-ozone sensors

- Environment Monitoring System: Built a networked sensor station (BME280 + ESP8266) for temperature, humidity, and pressure monitoring, with data upload to a cloud dashboard and low-power deep-sleep operation

- Face Shield Production (COVID, 6,000+ units): Organized and scaled PETG face-shield fabrication using laser-cut visors, injection-molded frames, and die-cut elastic (with co-worker)

- Battlebot: Designed and constructed a 3 lb combat robot featuring high-torque motors, LiPo power management, an all-wheel drivetrain optimized for speed and acceleration, and custom armor (with co-worker)

- High-Speed USB Current Device: Created a portable measurement device capable of sampling voltage and current at kilohertz rates-ideal for reverse-engineering ongoing tasks on electronics

- Medical Mattress Squeeze Table: Built a pneumatic squeeze-table assembly used in medical mattress manufacturing (with Co-Worker)

- Medical Mattress/Pad Heater: Built custom heating apparatus for sealing seams on medical mattress pads (with Co-Worker)

- Window Clip Manufacturing: Recreated obsolete window-clip parts via bulk additive manufacturing to replace thousands of failed components (with co-worker)

- Multi-Color FDM Production: Designed prototype parts for a consumer product and managed printing and post-processing of 500 multi-color FDM components

- Custom Drives Hardware: Designed and built drives electronics for three-phase AC motors, inductive motors, and DC motors in a single enclosure

- Topographic Map: Designed and created 12’x5’ topographic map for education and research center (with Co-Worker)

|

Advanced Manufacturing

▸

Advanced Additive Manufacturing Technologies

|

Collaboration with Co-Worker

|

2022 - Now

|

|

Operator and technician for additive manufacturing platforms. Sharing responsibility for hands‑on testing, day‑to‑day operation, and performing preventative maintenance and repairs.

Key systems managed:

- Xact XM200G (DMLS) - Metal powder handling, build chamber calibration, and print configuration/support creation

- Stratasys Objet 260 (PolyJet) - Multi‑material jetting setup, print head maintenance, and resin reservoir management

- Sinterit Lisa and Lisa X (Nylon SLS) - Powder bed preparation, laser power calibration, part depowdering workflows, and periodic chamber cleaning

- ProJet 660 Pro (Binder Jetting) - Binder delivery system checks, powder/agent replenishment, print tray realignment, and part post processing

- Markforged Mark 2 (Composite) - Print parameter tuning, fiber reinforcement strategies, and routine nozzle and drive‑system upkeep

- 23X BambuLab P1S FDM

- 4X BambuLab A1 FDM

- 1X BambuLab X1C FDM

- 2X BambuLab H2D FDM

- 2X Prusa XL Multi-Toolhead FDM

- 2X Prusa i3 MK4 FDM

- 16X Prusa i3 MK3s FDM

- 10X Prusa Mini FDM

- Formlabs Form 4 Resin

- Other miscellaneous printers (~75 total)

|

▸

Installation and Operation of Automated Pick-and-Place Assembly Line

|

Solo Project | Assistance with Moving Equipment

|

2019 - 2021

|

|

Led the installation, configuration, and operation of an automated pick-and-place assembly line, overseeing the import of the equipment and integrating it within our facility. This project required infrastructure planning, and teardown/rebuild of machinery to match our requirements.

The final setup included:

- Semi-Automatic Solder Paste Screen Printer (KAYO-5088)

- Manual Screen Printer (KAYO-P1000)

- Solder Paste Mixer (KAYO-500S)

- Automatic PCB Unloader (KAYO-50S)

- 2X Inspection Conveyors (KAYO-ICO6)

- Automatic Pick-and-Place Machine (KAYO-A4L)

- Convection Reflow Oven (KAYO-RF430)

- Automatic PCB Loader (KAYO-50P)

- Post Inspection Station (Digital Microscope/Testing Hardware)

|

▸

Design and Creation of Large-Scale Custom Printers

|

Design/Software | Project with Two Co-Workers

|

2015 - Now

|

|

Collaborated with two engineers to build a large-format Delta 3D printer prototype (10ft tall x 6ft wide) in 45 days. Although intended as a proof of concept, it produced usable parts up to 6ft tall.

Contributions:

- Kinematic Calibration: Leveraged OpenDACT to compute all machine kinematic parameters (arm lengths, endstop offsets, carriage geometry) for a 4 ft‑diameter bed

- Prototype Mechanical Design: Co‑designed structural linkages, custom brackets, and frame supports; specified and validated actuators and carriage assemblies

- Motion and Slicer Tuning: Developed and refined slicing profiles and motion parameters (speeds, accelerations, jerk limits)

- Delivery: Helped all stages-from concept through calibration and test prints-within a 45‑day schedule, and ended with a production‑capable prototype

|

▸

Print Farm Implementation and Management

|

Implemented with Co-Worker

|

2023 - Now

|

|

Worked with a co-worker to implement and operate a 30x BambuLab (P1S, X1 Series X1C and H2D, A1/A1 Mini) and 30x Prusa (MK4S, XL, MK3S, Mini) 3D printer farm, I helped optimize most aspects of our additive manufacturing workflow:

- Deployment and Configuration: Deployed and networked 30 BambuLab machines, standardizing slicer settings, and filament profiles to ensure consistent performance across P1S, X1C, H2D, A1, and A1 Minis. As well as an additional 30 Prusa machines, some offline and some managed by PrusaConnect

- Process Optimization: Tuned print profiles (temperatures, speeds, etc) for various materials-PLA, PETG, ASA, and composites

- Preventive Maintenance: Managed maintenance routines (lubrication, nozzle swaps)

- Quality Control and Troubleshooting: Diagnosed and resolved failures, and optimized processes for batch print jobs

|

▸

Injection Molding, Vacuum Forming, and Specialized Tooling Design

|

Face Shields with Co-Worker | Rest are Solo Projects

|

2011 - Now

|

|

Developed tooling solutions for injection molding, vacuum forming, and jig creation for repeated tasks:

- Injection‑Molded Face Shield Frames: Designed parts optimized for automated injection molding; tooling produced over 6,000 units for local clinics and hospitals

- Custom Vacuum‑Forming Bucks: Engineered master forms (bucks) for thermoforming complex geometries

- Visor‑Cutting Jigs: Created fixtures to hold and index vacuum-formed visors for manual and automated trimming

- PCB Stenciling Fixtures: Developed alignment jigs that secure PCBs for solder‑paste application

- Custom Production Centering Tools: Designed and fabricated fixtures for CO2 laser and fiber laser etching

|

▸

Other Manufacturing Technology Expertise

|

Share with Co-Worker

|

2020 - Now

|

|

Operator, programmer, and technician for a variety of manufacturing tools:

- 2X 3/4‑Axis CNC Milling with a Tormach 1100MX and 1X Tormach 440MX

- Engraving and cutting with BossLaser Fiber (1X) and CO₂ Lasers (2X) + Rotary

- CNC plasma cutting with a Tormach 1300PL

- Waterjet cutting with an Omax 1508

- 3D scanning with the Creaform Go!SCAN Spark and VXElements software suite

|

▸

Hyper-Converged Infrastructure (HCI) Design and Implementation

|

Solo Implementation, Management, and Operation

|

2019 - Now

|

|

Designed and implemented 20-node hyper-converged ProxmoxVE cluster, concurrently hosting up to 3,000-4,000 virtual machines and containers:

Specifications for this infrastructure:

- Scalable Compute Resources:

- Aggregate Capacity: 1,464 CPU cores and 10.8TiB RAM

- Per-Node: Up to 80 CPU cores and 784GiB RAM

- Accelerators: Select nodes equipped with NVIDIA RTX 8000 GPUs for GPU-accelerated tasks

- Customization: Users can request private compute infrastructures of up to 20-nodes, with Slurm-ready configurations

- Tiered Storage Solutions:

- Ceph-backed dynamic scaling across three performance tiers:

- SSD Base

- SSD Low-Latency

- HDD Base

- Total Capacity: ~211.52TiB with automated data distribution and resilience

- High-Speed Networking:

- Bandwidth: Two 25 GbE links per server (50 GbE aggregate) configured with 802.3ad LACP and MC-LAG for redundancy

- Features: RDMA, SDN, jumbo frames, and traffic prioritization

- Customization and security:

- Full user control over the software stack and container/VM images

- Software-defined networking with per-instance firewall rules

- Support for external network hosting and user-deployed firewalls

- Customized firewall rules per virtual instance depending on requirements

- Reliability and availability:

- Live scaling to adapt to workload demands without downtime

- Redundant network paths and daily backup/snapshot schedules

- Designed for security testing, scientific simulations, and parallel computing for data analysis and GPU-intensive applications

- Preconfigured templates for nested multi-machine clusters with SLURM

|

▸

Networking and Security

|

Solo Management and Operation

|

2020 - Now

|

|

Managed a variety of network configurations and their supporting software:

- Firewall Configuration and Management

- OPNSense / PFSense / SonicWall

- Deployed in active-active and active-standby high-availability pairs

- Application-aware filtering, IDS/IPS integration

- Role-based administration with audit logging

- Geo-IP blocking

- Linux Networking Configuration and Management

- VLAN trunking configuration, LACP setup, and network performance optimizations

- Linux-based firewall configuration and management

- OSPF routing configuration for small-scale clusters

- Optimization for Ceph networked storage

- VPN Configuration and Management

- OpenVPN Hosting

- Centralized server deployments for user and service tunnels

- RADIUS/LDAP integration for authentication

- Site-to-Site VPN Experience

- OPNSense ↔ OPNSense, OPNSense ↔ Palo Alto, SonicWall ↔ Palo Alto

- Networking Hardware Ecosystem

- MC-LAG with ECS Aggregation Switches

- Active/active link aggregation across top-of-rack and spine layers for redundancy

- VLAN segmentation and access control lists for tenant isolation

- Deployment of Wi-Fi 7 and Wi-Fi 6/6E networks

- IP Security Cameras and NVR Integration

- PoE/PoE+ power delivery

- Centralized NVR for video recording

- Software-Defined Networking for Cluster Overlays

- Custom L2/L3 overlays

- Proxmox SDN module enabling per-tenant virtual networks within the cluster

- Performance Monitoring with NetFlow

- Flow telemetry to identify congestion with traffic paths

- Cloudflare Zero Trust

- Email-Based Access Controls

- Secure web application access using one-time email verification links

- Granular policy enforcement per URL, with logging of all user sessions

- Remote Workstation and Internal App Protection

- Proxy published internal services (RDP, SSH, web UIs) through Zero Trust tunnels

- Device posture checks via WARP client

|

▸

Active Directory Management

|

Solo Management and Operation

|

2019 - Now

|

|

Active Directory Management (500+ users)

- Self-Service Password Management

- Automated portals enable users to reset and change their own passwords securely

- MFA using TOTP for identity verification

- Recurring Self-Audits

- Scheduled scans of user accounts and group memberships to detect inactive or orphaned objects

- Automated reports on password-policy compliance and access entitlements

- Scalability and Concurrency

- Supports ~500 users without performance degradation

- High-availability domain controllers and load-balanced authentication

- AD-Backed Network Access

- Wi-Fi Access: 802.1X authentication against AD for per-user connectivity

- VPN Access: AD credential validation for remote-user tunnels

- Group-Based Policy Management

- Role and department-based group management and network VLAN assignments

- Dynamic group memberships allow policies to follow users as they change roles

- Group Provisioning

- Integration with HR/authoritative systems to import new users and remove old users

- AD group creation and membership updates via scripted exports

|

- Electronics and CAD: Altium Designer, KiCad, Autodesk Fusion 360, MATLAB

- Server and Virtualization: Proxmox VE, Ceph, VMWare vSphere, Windows Server, Hyper-V, Ansible, PDQ Deploy

- Programming Languages: C/C++, Python, JavaScript, C# (WPF, Unity), Bash, PowerShell, Make

- Environments and Administration: Linux and Windows administration, embedded platforms (ARM, RISC), GitHub Automation

- Miscellaneous: Blender, Adobe Suite (Photoshop, Illustrator, After Effects, Substance Painter), GIMP/Inkscape

▸

Coela.dev Website

| Github |

2025 - Now

|

The site’s backend uses Ruby and Jekyll to compile Markdown and Liquid templates into a static site on push. A GitHub CI workflow rebuilds and deploys the site on changes to the main branch. On the front end, an HTML5 Canvas script animates sine-wave effects, and CSS with JavaScript handles glitch-text animations for headings.

|